The archives

Return to the

Now spinning

page

Spring explorations

March - April 2007

01 May 2007

April came to a close with the end of a narrow silk weaving, numerous balls of new knitting yarns stacked next to the spindles that created them, and a whole set of new projects added to The List. It had been a month of active spinning, with shiny silk yarns, blends of silk and wool, pure Romney wool yarns, some test spindles, and a number of things that haven't been mentioned here; and the next few months are bright and brimming with new ideas.

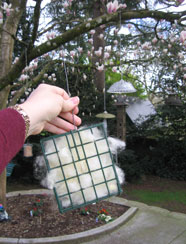

The real action today, though, is outside the house, where the discarded wool fuzz and silk fiber is about to fly off to a brand-new destiny. Click on the thumbnails for the full effect:

Isn't springtime grand??

29 April 2007

Meanwhile in another room, on another spindle....

More accurately, this story should start with Once upon a time, there was a small baggie filled with space-dyed bombyx silk....

Some people plan their final projects, then find the fiber and spin the yarn appropriate to their plans. It usually happens the other way around with me, and that's certainly the case this time! A small baggie of bombyx silk fiber, space-dyed in blues, turquoises, and purples, had come with me on my travels. It wasn't enough fiber for any large-scale project; but it was pretty, and spinning it was a lovely romp through a wide shimmer of color.

As she watched me spin, my mother said, "What are you going to make with that? Bookmarks??" ...I can recognize a good idea when I hear one, and suddenly this small skein of pretty silk had a destiny! :-)

The little skein that came off the spindle contained just 74 yards of two-ply yarn. By itself, that would have been plenty for the bookmarks; but woven entirely of this yarn, the bookmarks risked looking a little smudgy, with soft colors flowing a little too freely into each other. Some green-gold tussah silk yarn, spun on a different spindle, on a different day, in a different room, gave me just what I needed for a couple of contrasting stripes.

I wound a two-yard warp for my little semi-rigid heddle (left), threaded it, and started weaving. As it progressed, the band's texture proved pleasing: firm with a faintly nubbly surface. The pronounced sheen of the yarn becomes a subtle sparkle in the woven band, and the watercolor shades deepen slightly. The colors wander softly through the bookmark as imagined, accented with two bright pinstripes.

The change in the sheen is an interesting one. Silk yarns spun from top or sliver always are more lustrous when they have less twist, shifting to a quieter sparkle when the twist is firmer; so it makes sense that a lustrous yarn woven as I'm doing would make a band with less sheen than the original yarn -- but I hadn't really expected it. It's nice, though. The photo doesn't quite catch the effect, but the band has a very pleasant sparkle, with the light catching on each tiny "nubble" of the weave. (Click on thumbnail at right for a close-up view.)

So far, so good; but not all is sunny and bright in this picture. I'm using the same yarn for weft as I've used for warp, and those medium-twist yarns (with nice sheen!) are not at all happy about being handled on the little belt shuttle (left). If you look closely, you can see that with handling, the yarns spread and fuzz out, binding themselves to other parts of the yarn on the shuttle.

It's not an insurmountable problem, but it was a surprise -- and it's taught me something so it won't happen again: my next silk weft will be firmly twisted and smooth.

Actually, my next silk warp and weft for narrow weavings may very well be spun from a "stretched-cocoon" preparation -- caps or hankies. Those fibers are long enough and strong enough to be spun into a high-sheen yarn that will stand up to abrasion and handling. Something to look forward to!

End notes, for inquiring minds

♦ The pretty space-dyed bombyx top was prepared by the people at Oliver Twists in England. They have no website, but they participate in many craft and stitching shows throughout the year, mostly in the U.K. Their yarns and dyed fibers are available from a number of suppliers.

♦ The semi-rigid heddle is a design that came to me in a dream and is now lovingly made by me in my own living room. If you'd like one of your very own, they are available (click here for more information).

21 April 2007

It's hard to believe this: I'm knitting swatch samples for socks! Because I'm not one of Nature's knitters, this sudden development is as unexpected and dramatic as, say, the moon falling on California (though a lot of people actually expect that to happen, which makes it much more likely than my starting a knitting project!).

It all began when Mom and I were in a yarn store and found two identical sets of double-pointed knitting needles for $1.00 each. We bought them, of course -- after all, you can't have too many knitting needles, even if you don't really knit. ...I'm speaking for myself when I say that, because unlike me, Mom has been a prolific knitter in the past. She started knitting when she was five, and for as long as I can remember she always had some project in progress. Until recently.

My mother grew up in the Maritime provinces of Canada -- New Brunswick, to be precise. As a young woman she answered the call of her country and knit socks for "our fellows in the military" who were fighting in Europe. World War II was in full swing, and Canada had joined the fray early on and stayed all the way to the end. It was a long engagement. And my mother knit socks, as did many other young women across Canada.

She says the agency organizing this knitting effort gave them guidelines on how to knit the socks and furnished the wool for knitting. When you went to the place and turned in a pair of finished socks, you got the wool for the next pair. ...When I was small, I used to admire Mom's knitting needles: steel double-pointed needles in several sizes. They were cool and dense and smooth, and I knew she'd used them to knit socks -- which I'd never seen her do, so it seemed quite magical.

Anyway, to come back to today: here we were, the two of us, each with a new set of gold aluminum double-pointed needles. And several balls of yarn had come from the silk-and-wool blending project described a few days ago -- spindle-spun, all, and just right for sturdy knitting.

Let me interject here that Mom has had pieces of her memory go missing over the past several years, and she hasn't touched her knitting needles for at least a decade. Her interest in the double-pointed needles looked like a good sign; and as I knit the flat swatch, I could see she was moderately interested. So I kept going.

When I cast on 32 stitches (for a mini sock -- less daunting than full-size) and distributed them among three double-pointed needles, she was watching me carefully. By the time I'd completed three rounds of K2P2 ribbing, she was in her bedroom, looking for her new set of double-points. And soon we were knitting together!

We knit together, side by side, all afternoon. At first she was unsure of herself, but soon she was watching in delight as her hands remembered what to do -- and her ability to describe her techniques followed shortly thereafter. (Never underestimate the power of the hands to remember things we think we've forgotten!)

We knit with different tensions, as our two samples show. Mine (left) is firmly knit -- not quite too tight, but firm. Mom's (right) is supple and fluid, with a stockinette stitch that would be a delight to wear. They're both good, and they both reflect the hands that knit them.

Mom enjoyed teaching me how to knit (reteaching, actually -- the first teaching session happened a little more than 40 years ago). As her confidence returned, I asked if she'd let me take a movie of her technique with my digital camera; and the picture of her hands (right) is from that little video.

As I held the camera, she explained her techniques, her special tricks for avoiding the dread Gap that can happen when you switch from one double-pointed needle to the next, her way of counting stitches and rows, her manner of tensioning the yarn. It was a grand afternoon. :-)

As I held the camera, she explained her techniques, her special tricks for avoiding the dread Gap that can happen when you switch from one double-pointed needle to the next, her way of counting stitches and rows, her manner of tensioning the yarn. It was a grand afternoon. :-)

As I type this, our sock samples aren't yet finished; but they will be. Our next task: turning the heels!

Luckily, I have a good teacher.

05 April 2007

Travel spinning in action: this is a wool-silk blend much like the one I was spinning last month. I like the way the silk adds sheen to the wool, and it adds a whisper of softness to the feel as well.

To prepare it for spinning, the wool was teased, then layered with a bit of tussah silk on the small handcards, and the two were blended together. It took just two rounds of carding to prepare these rolags. The resulting yarn has gentle streaking in it, but they're streaks of silk -- like streaks of soft light.

One of the side-effects of preparing your own fiber is the small pile of "fuzz" that you don't want to put in your yarn. These are the second cuts, the neps, the snarls, the little half-spun wisps you don't feel like teasing out....

As I was carding and thinking of the growing pile of fuzzy debris beside me, I glanced out the window and saw a pair of sparrows making eyes at each other. This timing is perfect: it's spring!

A wide-mesh suet feeder had been tucked carefully away on a basement shelf, and its form was so well-suited to holding nesting material that you could swear it had been made for the job (right).

Yesterday I had the grand pleasure of watching a sparrow pull out a clump of wool that was just as big as he was! It was so big, he could hardly fly with it -- but he was careful not to share it with any of the other birds.

They're lining their nests with soft wool and silk, here in the Pacific Northwest.

Happy, happy creatures. :-)

30 March 2007

Spinning while travelling, anyway. I'll be away from home for a little more than a month, and this picture shows the Survival Kit I've brought with me.

You can see a variety of fiber: silk and two kinds of wool show clearly in the photo, and baggies of Tencel, bamboo, and trilobal nylon are lurking in the shadows behind them. Packed in zip-lock bags, you can squeeze the air out to keep them from being too bulky in your suitcase (and talk about great padding!).

The equipment is compact, but quite adequate for a month (or more!) of work. As you can see there are several weights of spindle, a small niddy-noddy, and a cute little pair of handcards.

The handcards are the newest addition to my travel bag. In the past, I've carried a pair of flick carders for wool processing -- two flick carders used together do a very nice job of carding without taking up half of your suitcase space. The batts from flick carders are very small, though; and these new cards can process almost twice as much fiber at a time.

Their manufacturer intended them for grooming animals, not for preparing fiber; but they seem quite happy in this new role. They're sturdy but lightweight, with comfortable handles and flat metal backs (the metal is covered so there are no sharp edges). I've seen listings for "children's cards" that look to be about this same size.

So -- spinning on the road?? You betcha!

End notes, for inquiring minds

♦ The beautiful spindles with flowers and butterflies on them were made by Shannon Wilson of Keizer, Oregon. Their whorls are covered with carefully-worked polymer clay (in other words, those lovely designs were built, not painted!). She sells her spindles on eBay under the name "sdlinky" (click here to see her listings).

♦ The tussah silk top came from Fibrecrafts in Surrey, England (click here for more information).

♦ The small handcards were originally intended for grooming animals. When I remember where I got them, I'll share that information.

25 March 2007

I'm listening to advice, whether I want to or not.

After careful study (right), she's concluded that my blends of wool and silk are okay, but when it comes to real yarn, nothing can beat the bast fibers.

And having considered all sides of the question, she's convinced that little dinky yarns like the ones I've been spinning aren't worth all that trouble. I should be making good, chunky cordage that a girl can sink her teeth into!

You can see she's being patient with me (left). She knows it takes time to transform thought into action.

She looks calm, but she means business.

Bast fibers. (purr, purr, purr)

Sisal. (purr, purr, purr)

Think about it. (purr, purr, purr)

...Message received!

(But she'll have to wait a while for the results.)

20 March 2007

When the wheel calls, you can't wait!

This bobbinful of yarn is a rough 50-50 blend of wool and silk. The wool is from an unidentified (downy) breed of sheep and was the greasy fleece in which parts of the red wheel were packed for shipping.

Truth told, I'd planned to just card the fibers and set them aside (having learned my lesson from last week's misadventure). But they were pretty! ...Let's backtrack so you can see where this blend came from.

Just before my back blew out, I'd washed the wool and revealed its pleasant, springy character. While it's not baby-soft, it's also not a rough wool; it has a medium crimp and is fairly fine. The fleece has an overall creamy color with hints of vanilla, and its locks have faintly beige tips.

Spindle spinning often saves the day around here (and all spindlers reading this will know exactly what that means). I'd spindle-spun and plied a small skein of this downy wool, just to test it; and though it's nice enough, it becomes completely matte as soon as it's spun.

In addition to that, after spinning the wool's creamy color takes on a yellow with uncomfortable tones of butterfat (upper, right).

In addition to that, after spinning the wool's creamy color takes on a yellow with uncomfortable tones of butterfat (upper, right).

Blending this wool with silk (quick work with hand cards) shifts the color toward honey-beige and gives it a satisfying sheen. It also gives the yarn a wonderful feel: softer to the touch, less springy (but still elastic), a nicer drape, more sensuous. It's now more of a grown-up yarn.

So I carded a basketful of nice little cream-and-sheen rolags. And that was when the red wheel started murmuring from its corner: It's only for an evening, it can't hurt you, the rolags are too pretty to leave as poufs in the basket.... Darned wheel.

I learn slowly, but I do learn: this time, instead of using my regular spinning stool, I installed myself in the rocking chair with a heating pad against my back. The rocking chair is shorter than the stool, and that eased some of the strain I'd had last time -- and it worked! This bobbin was filled over the course of the evening in complete comfort, deliciously spun on a perfectly silent wheel, under the watchful (but sleepy) gaze of the cat.

Not bad. :-)

16 March 2007

Let this be a lesson to you: it's really, really stupid to spend an evening spinning on a wheel when your back is in a delicate condition.

Do as I say, not as I do. When you are resting your back, staring at the ceiling, taking mental inventory of your fiber stash and thinking of all the things you'll do as soon as all is well, do not succumb to temptation. Not even if you're starving for a fiber fix.

Silk is one of the strongest materials occurring in Nature. We, on the other hand, are weak.

There's really nothing more to say, is there? This tussah silk was completely delicious, and the memory of how it flowed through my fingers eases the discomfort of this relapse....

End notes, for inquiring minds

♦ This delicious tussah top came from Fibrecrafts in Surrey, England (click here for more information).

♦ The wheel supporting it was made many years ago by Louet and is described elsewhere in these pages.

12 March 2007

A few days ago I wrenched my back while running the vacuum cleaner (the moral: avoid housework if you can possibly put it off!). The worst has passed, but everything is moving much more slowly right now....

Some things won't be postponed, though: the new/old red wheel was calling out to be repaired and used (nag, nag, nag!). The broken hinge was the main obstacle to taking the wheel for its first spinning run, so it was first on the List.

While these photos cut to the chase and show the end result, they don't show the most frustrating part of the operation: the quest for a small piece of leather. Despite all the shoe-repair shops and craft stores in my area, no leather was available anywhere! Finally, an old belt from my wardrobe came selflessly to the rescue -- and there's now extra black leather on hand for when the other hinge fails.

These leather hinges are very simple. A piece of leather is anchored to the top of the front cross-bar, then folds down between the heel of the treadle and the bar. It's anchored to the heel end of the treadle, then folds flush with the treadle's underside and is anchored there.

As soon as the treadle was functional, I put a cotton drive band on the wheel and tried it out!

I'd been concerned that the drive wheel and spinning head would not be aligned well enough to work (left). If the alignment between the two isn't clean enough, the wheel will "throw" the drive band off one pulley or the other, or off the drive wheel itself; and then the air all around the spinning wheel turns blue and no one has a nice time any more. :-/

With bated breath, I tightened the drive band tension and gently started treadling... and everything was fine! The wheel spun with a decided limp, and a minor clunking noise -- but it kept its drive band!

The first bobbinful was medium wool of no importance, fiber sacrificed to the Cause of the Wheel. By the time the bobbin was half-filled, it was clear that the limping and clunking came from one of the posts supporting the drive wheel: it was loose and moved as the wheel turned. After emptying the bobbin, then, I set to work with wood glue (and delicate tools) and braced the reglued post in position overnight.

The next morning, I removed the braces and gently wiggled the wheel-support post. It was stable! Even better, the alignment of the drive band was now darned close to True (right)! Granted, the direction of the line between drive wheel and pulleys is a little odd (it's usually parallel with the sides of the bench, not at a diagonal -- right?); but a straight line is a straight line, and I don't want to be ungrateful!

A bit of "test" treadling convinced me that everything was running much more smoothly than before, so I set the wheel to work, for real! Its first task was to spin some flax tow into a drive band, which it would then use in its future activities. The tow was dry-spun, then plied with a polyester binder thread that echoes the red of the wheel (left). ...And the spinning was a grand pleasure!

Sharp eyes will have noticed that the rim of the drive wheel has been lined with some kind of fabric (it feels like linen, but could be cotton). This is the first time I've seen something like this on a wheel, and though it struck me as strange, it turns out to be an effective way of making sure the drive band gets good traction on the wheel. Many wheels need dressing on their drive bands; but this one won't.

The wheel and I are now both very happy -- and one of us (not me) runs silently! :-)

End notes, for inquiring minds

♦ The flax tow for the drive band was in sliver form and can be spun either dry or wet. Tow sliver is available from many sources; this particular batch came from Fibrecrafts in Surrey, England (click here for more information).

09 March 2007

My wistful wanderings through the halls of eBay led to a binding agreement last week (my husband was out of town, and whatever's a girl to do with her sudden spare time??). After a flurry of friendly e-mails, money changed hands; and this week the package arrived.

Isn't that just one of the most promising boxes you've ever seen? :-) It's amazing it stayed unopened long enough to have its picture taken.

Even though I knew what was inside (right), it was exciting to cut the packing tape and pull out layers of soft stuffings, unveiling the prize, bit by bit.

The packaging was masterful. The most delicate wheel parts (the flyer-and-bobbin assembly and the distaff) had been swathed in greasy fleece and placed in their own boxes; and those smaller boxes served as packing supports for the larger parts of the wheel.

Once it had been unpacked and put together, I stood back to admire it. The most striking thing about the wheel when you see it in person (which you wouldn't suspect from looking at its photo) is that it's small: the top of the distaff comes to just barely above my waist, and the hub of the drive wheel is level with my knees.

The wheel came from Holland, but the person selling it could tell me little about it. She said she'd found a photo of a similar wheel that apparently came from Flanders, the flatland area stretching from northern France through Belgium -- an area still reknowned for its production of fine flax.

And a flax wheel it is! The lovely tow distaff (left) bears witness to that, as do the grooves worn into the wood of the flyer, where new yarn has passed on its way to the bobbin. The difference in size between the two drive pulleys suggests that this wheel is a fast spinner, despite its small stature.

It's interesting to listen to an old wheel and imagine its history. This wheel was clearly used, but it was also well-treated. The stains near the orifice and at the hub of the wheel show it was kept oiled. Its paint is intact except in areas where the wheel would normally be touched frequently: the adjustment knob, the treadle, the front maiden, the upper right wheel spoke (where you nudge the wheel to get it started).

Whatever its origins, it was a dressy little wheel when it was new. Its decorative turnings are not ornate, but they're all capped with tiny ivory finials. The treadle has a narrow stripe of gold paint outlining its contours. Even the bench boasts a modest decoration: a small bouquet of warm-toned roses, painted just under the top layer of varnish.

It needs a few minor repairs before it can go for its first spin here in its new home. The treadle, rather than being mounted to a pivoting rod, is attached to a fixed rod with leather hinges; and one of those hinges has broken.

The repair is simple and likely to happen soon. Stay tuned for the next report!

06 March 2007

The past week has been productive: I've been washing fleece! And though the results are really lovely (left), this could have been another of those Cautionary Tales I keep threatening to share.

The past week has been productive: I've been washing fleece! And though the results are really lovely (left), this could have been another of those Cautionary Tales I keep threatening to share.

Let me describe the events exactly as they unfolded.

Last summer while I was visiting family in the Pacific Northwest, I went travelling and bought a fleece: a lovely Romney fleece, in medium grey, with medium crimp, medium coarseness, a medium-length staple -- in short, exactly the wool I needed to fill a big void in my spinning stash (i.e., the void right in the middle!).

It was a normal-sized Romney fleece -- which is to say, larger than any piece of luggage I own. To bring it home in my suitcase I needed to find a way to make it smaller. The result (right) is what happens when you vacuum-pack a nicely-rolled, full-size fleece. In its uncompressed form, it would fill my huge armchair to overflowing; after vacuum-packing, it was two feet wide and less than three inches thick. ...I must add that it took two of us, struggling mightily, to get the uncompressed fleece stuffed into the bag!

These vacuum bags are very useful. Basically, you insert whatever-it-is into the bag, seal the bag, then use your vacuum cleaner to suck most of the air out through the bag's special valve. I probably shouldn't admit this (lest the gods of politically-correct spinning strike me down), but I have stored wool in vacuum bags -- many times. If the wool is clean and completely dry, it's just not a problem; and it's an excellent barrier against those wool-eating insects which will remain nameless until I absolutely have to talk about them.

But back to the point: wool that's been compressed in a vacuum bag still has all of its springy memory and starts to expand back to its natural form as soon as it's removed from the bag (left). Because this fleece was still greasy and had aged seven months in the bag, it was harder to unfold and unroll than it would have been, fresh.

Even so, it did unfold; and once out in the open air of the living room, it regained its original, magnificent form(right). Granted, the tips of the locks are a little flatter than they had been last summer; but as the fleece was about to be plunged into a fragrant, steaming bath, that wasn't a worry.

Even so, it did unfold; and once out in the open air of the living room, it regained its original, magnificent form(right). Granted, the tips of the locks are a little flatter than they had been last summer; but as the fleece was about to be plunged into a fragrant, steaming bath, that wasn't a worry.

One of the things I love about being the one who washes the wool I spin is that it gives me a better overview of the fleece than I'd get if, for example, I'd sent it out to be processed -- or if I'd purchased ready-to-spin roving. That overview gives me information about the wool that I couldn't get any other way -- extraordinarily useful information.

Consider this fleece, for example. In some parts of the fleece, the locks are well-formed, with a firm, even crimp (left). In other parts (right), the locks are a little more disheveled, with wavy, curly crimp that couldn't stay in regimented lines if it wanted to.

And how is that useful?? It helps me decide both what this wool should become and how to process the wool to get that final result. The nature of the crimp shows itself in the yarn: springier, crimpier fibers make for loftier, more elastic yarns; and looser-crimped fibers tend to make yarns that are strong, but not stretchy. As for the locks themselves, their structure may guide my fiber-processing: well-defined locks are an undiluted joy to comb; bubbly, undisciplined locks with curly tips are more pleasant to process by carding.

These are all things that run through my mind as I admire a greasy fleece laid out full-size on my living room floor. (By the way, the cat loves this part of wool processing with all of her fuzzy little heart.)

The next steps are well-documented in most texts and websites dealing with getting wool ready to spin, and my procedures don't vary much from the norm. We have a bathtub in our laundry room, which makes it easy to wash fairly large batches of wool at a time; and that bathtub is getting filled with hot water any time I'm unrolling a fleece in the living room. Unless the fleece is dry or brittle, I'll use hot water through the entire wash-and-rinse process. ...Following the final rinse, the bags of wool get lifted out of the tub and placed directly into my washing machine to spin out the water. (That's Spin Cycle only, no water action at all.) Extracting the water this way speeds the drying time tremendously.

The results (left)) are heart-warming as soon as you spread the clean wool out, and it just gets better as the puffy pile dries.

When I was a new spinner, I was taught to start teasing the wool right away and pulling it apart while it was wet -- but I don't do that any more. Wool is stronger when dry, and any minor felting that needs to be pulled apart can very easily wait until the wool is dry and less vulnerable.

The actual color of this amazing grey Romney fleece shows much better in the close-up photo, which was taken with natural daylight. There are nuances in it that tend toward violet, and they're profoundly pleasing! Those interesting nuances are still there in the yarn, too....

It took one afternoon to sort and wash this wool, then another day for the wool to dry. For such a wealth of lovely fiber, that's not a big time investment; and I have several weeks' spinning ahead of me before all this wool becomes yarn.

But that's not the end of the story.

Even though I can wash fairly big quantities of wool at a time, I was able to process only half of this wonderful fleece! The rest (left) has been placed back into its vacuum bag, where it will wait for another auspicious wash day.

End notes, for inquiring minds

♦ The beautiful Romney fleece came from Spring Hill Farm Romneys, a handspinner's farm on the Olympic Peninsula of Washington State. The fleece was grown by a ram named Simon (in the words of Margaret, his owner: "He was named for Simon Templar – tall, dark, and handsome.") Click here for more information (that is, for more info on the farm, not more on The Saint).

♦ The amazing vacuum bag is known as The Space Bag, available from www.spacebag.com. (Be forewarned that they have a video on almost every webpage -- nothing malicious, but it can be slow).

02 March 2007

It's amazing how one thing can lead to another. Last week I was desperate for a fetch hook, and that led me to learn how to work with galvanized steel wire. In the time since, I've learned I can do surprising things with wires in other materials... and other weights!

The latest in my low-profile, living-room projects (right) is made from thick brass wire (too thick for hooks). It's a shawl pin -- and it couldn't get much simpler: its tail slides easily between stitches of two layers of a shawl, and its zig-zaggy shape keeps the pin in place.

It's worth mentioning that the photo also shows one of my rare excursions into knitting: the red-toned shawl. ...In the bedroom, there's also a green-toned shawl and a jewel-toned trilobal nylon shawl. Knitting and I don't usually spend much time together, but I had full-to-toppling bags of small handspun skeins, and the yarns just begged to be put together in something stripey where their varying textures and materials wouldn't matter too much.

When the stash insists on something, it's wisest to obey! :-)

The result was three very useful garments -- which are even more useful now that I have a pin to hold them in place. All three are garter-stitch shawls started with one stitch at the lower center back, with increases of one stitch at the center back and at the end of each row until the shawl has reached its final size. A crocheted border along the two lower edges gives the shawls weight and body.

Return to top of page

Return to the Now spinning page